The customizable balance of ENULEC® technology

Imagine a soap bubble

The soap bubble does not form a uniform surface. The alkaline film varies by millionths of a millimeter, so that the light in the visible range of approx. 400-720 nm is reflected at the surface of the soap bubble at different frequencies and we perceive the soap bubble with its magnificent rainbow colors.

The situation is similar with film materials. To the human eye, the film forms a homogeneous surface. A closer look under the microscope would show that the surface of the film is not homogeneous either, but varies by millionths of a millimeter.

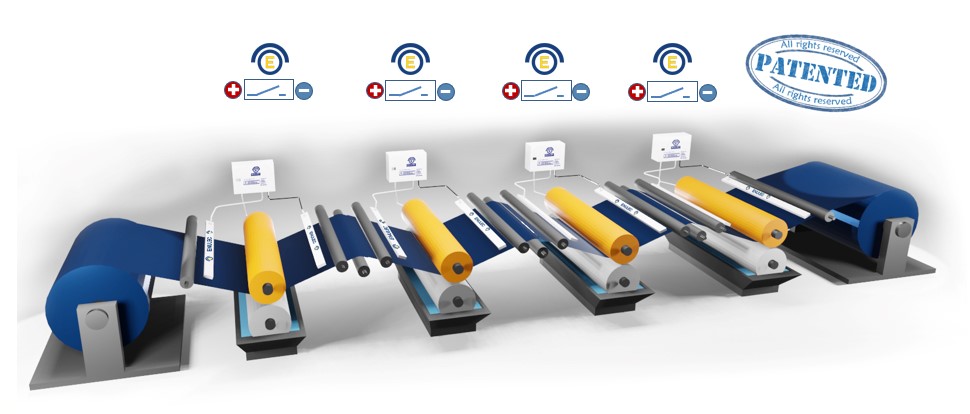

Comparable to the color areas of the soap bubble, these areas merge into each other and thus create varying areas of electrostatic charge, which can be increased during the production process or reduced by using an ENULLEC® ESA System. As a rule, films tend to have an excess of static charges at the end of the production run. The ENULEC ESA ROTO-Film PRO specifically counteracts this effect with its patented technology.

However, there are exceptions to the rule

e.g. when using PU-paints with a high solvent content

A field report:

A current example from a leading European customer in the packaging industry shows you how you can really reduce all static charges to an absolute minimum, even with PU-varnish – with the help of our ROTO-FILM-PRO technology including our inline measurement and EST-DC-LDS discharge.

The customer had received a new rotogravure printing press and until now had always had problems with trapped static charges when printing with white PU ink on a film substrate.

Suitable countermeasures adapted to the special production situation using our patented ROTO-FILM-PRO technology enabled the optimum ESA connection to be determined in a short time and all static charges to be eliminated.

For this customer, the investment in the ENULEC ESA ROTO-Film PRO technology has significantly improved his quality management, as a result customer satisfaction has increased significantly.

For you this means:

Significantly higher yields, time savings and more satisfied customers!