AUTONOMOUS ENULEC® Technologie

Only available from ENULEC®

Process optimized automation

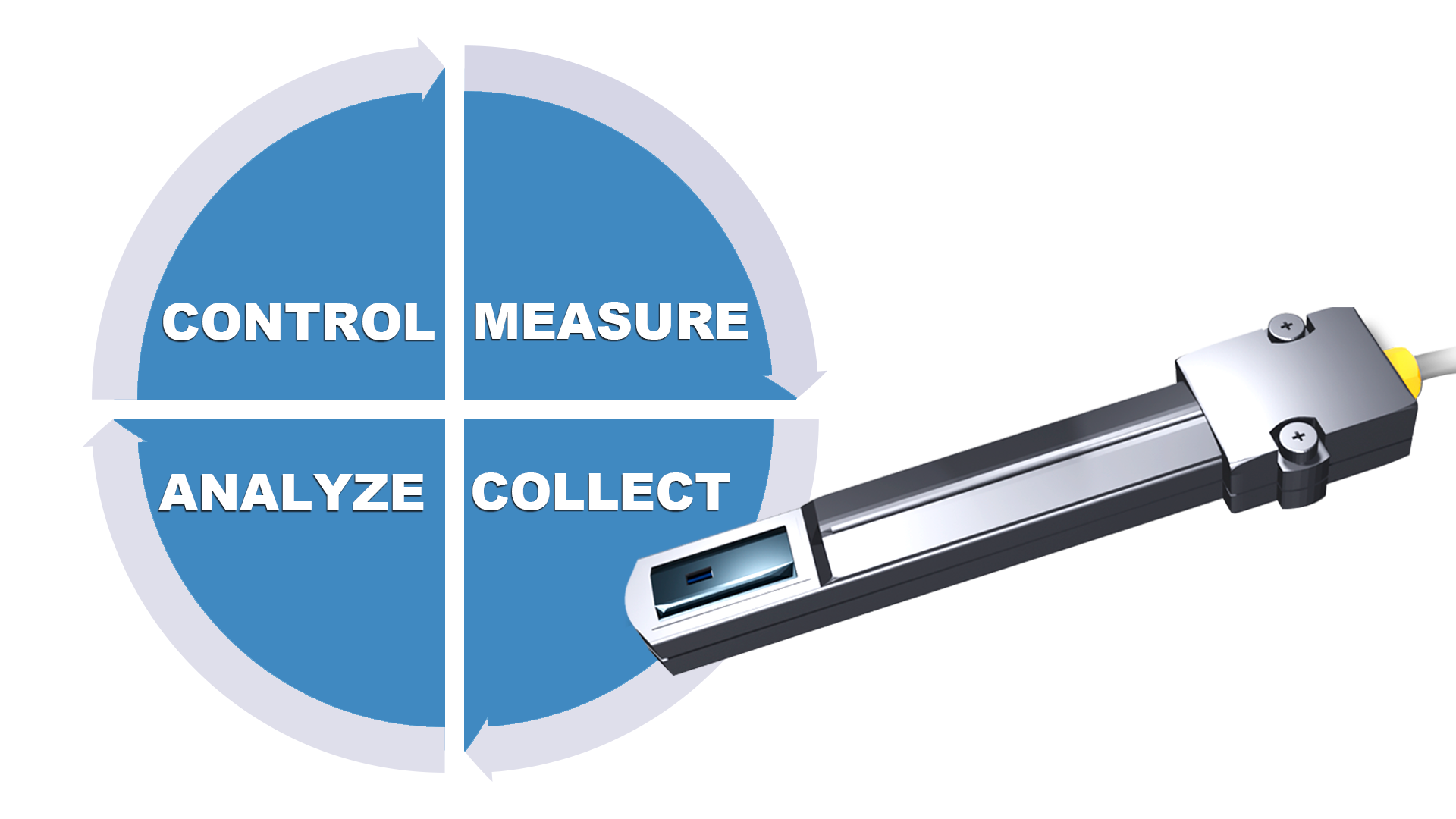

ESA Static Loop 360° is a patented further development of the Enulec ESA technology. Its core is an iterative process of static charge monitoring. Based on four patent technologies from ENULEC, this autonomously acting system guarantees maximum safety, especially in potentially explosive atmospheres.

___________________________

Machine, tools and IT application are in continuous dialog with each other and thus enable process-optimized automation of the workflow. All data important for your production process is made visible, merged and evaluated. The result is an automation process that is adapted to the production environment and the materials used. Static changes and sources of error are detected at an early stage and the entire production process is optimized and made safer.

“Honorable Mention” in the category Technical Innovation – Press

The jury of the Gravure Aimcal Alliance credits this innovation with a “great safety performance” in reducing static charges. This is associated with particularly efficient control of the production process and, as a result, serious cost savings.

For maximum safety in potentially explosive atmospheres

Maximum reduction of static charge on film webs is of great importance for applications in the fields of printing and converting. This is because it helps to prevent sparking during production and thus material damage, especially with thin film substrates, as well as accidents at work.

In addition, there is a risk of single-pole ESA charges in the printing nip additionally increasing the static charge in printing units, rewinders, slitters and laminators. To overcome this challenge, Enulec has optimized the collection and analysis of data by transferring the recorded values into an automated process. For this purpose, ESA and unloading systems communicate for the first time without restriction with the production machine via several variables and can be optimally managed and set depending on the parameters or configuration of the respective production machine.

A static energy algorithm calculates the output of ESA with autonomous adjustment of charge levels and polarities to achieve an optimal balanced static charge of each pressure unit to neutralize the static charge in the low pressure line. The system has a patented safety grounding mechanism that safely grounds electrostatic charges that reach a threshold of 2 kV.

Important points and integrated patents:

- Inline measuring probes for measuring web static on each pressure unit integrated in the ESA1000 system.

- Algorithmic calculation of the measured values to reduce electrostatics in the production process

- Autonomous adjustment of ESA polarity and control values for optimal reduction of static charge in the printing process.

- Automatic shutdown against ground when nip values reach a threshold of 2 kv.