The perfect balance of ENULEC® technology

Only available from ENULEC®

Pioneering Static Innovations

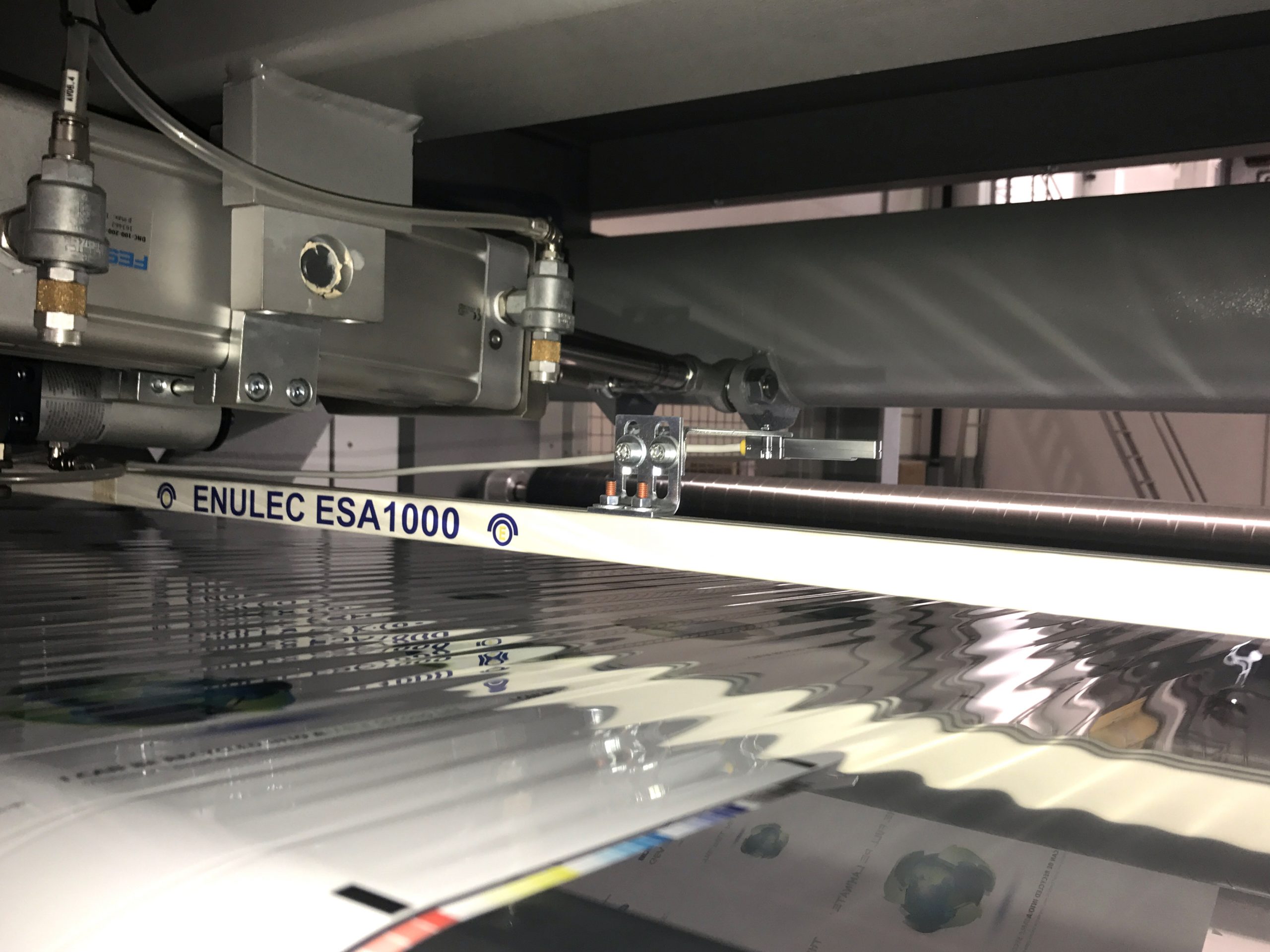

Increased reliability, safety and efficiency are the stringent demands that customers place on state-of-the-art package printing process. With the ENULEC ESA innovations like ROTO-Film PRO and ROTOGreen advanced, the high demands for optimum control of electrostatic charges and thus high safety in the printing and converting process are being fulfilled.

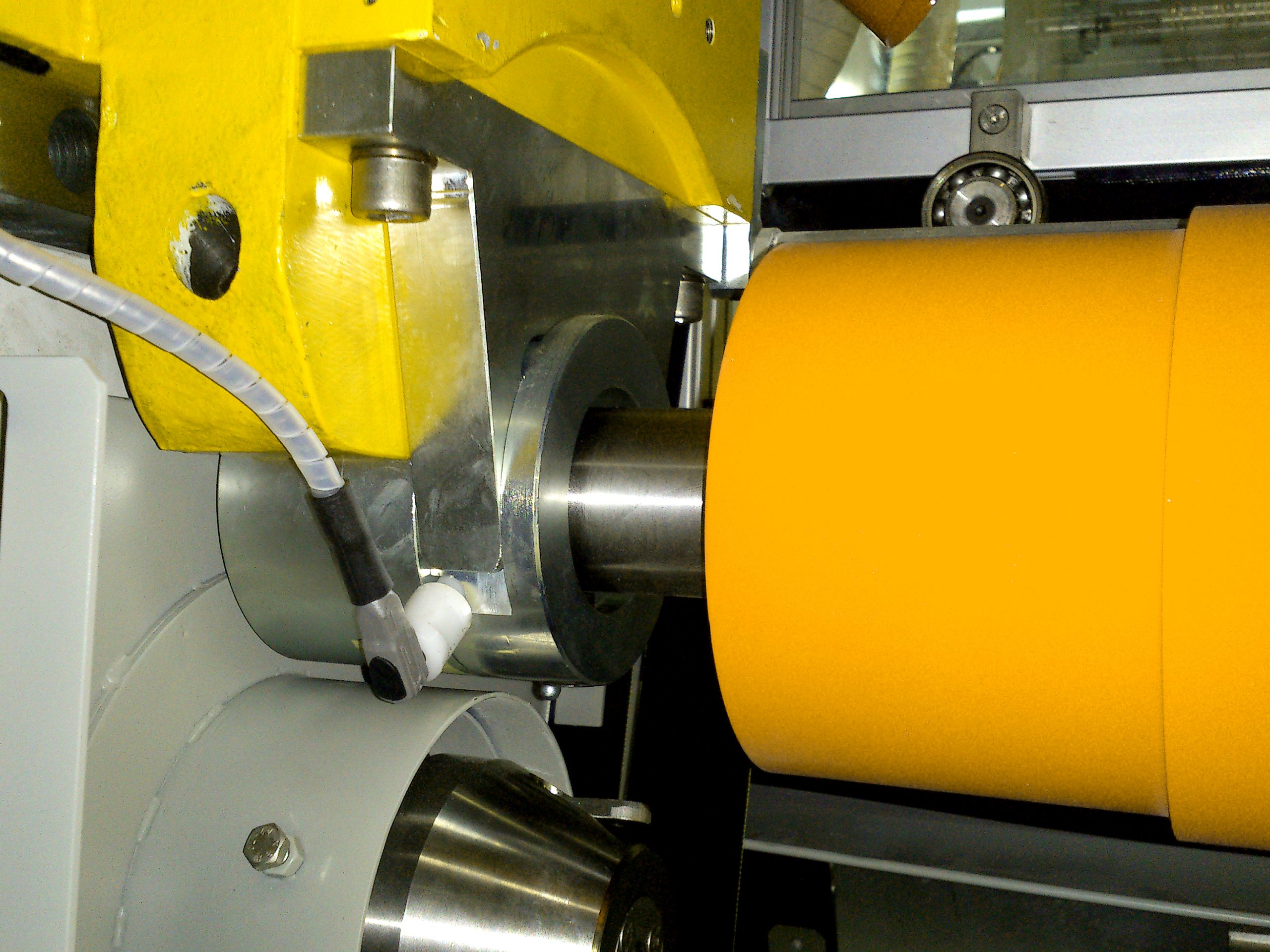

Furthermore, with its capacity-free high voltage generator and higher-frequency voltage superposition, ESA Roto-Film Pro counteracts the effect of charge buildup. This ensures constant ESA performance even under difficult printing conditions and with different film substrates. Capacity-free high voltage generation on the impression roller achieves the best print results and considerably reduces wastage and set-up times in a gravure press. This unique technology fully breaks up unwanted electric double layers and successfully eliminates disruptive static charges.

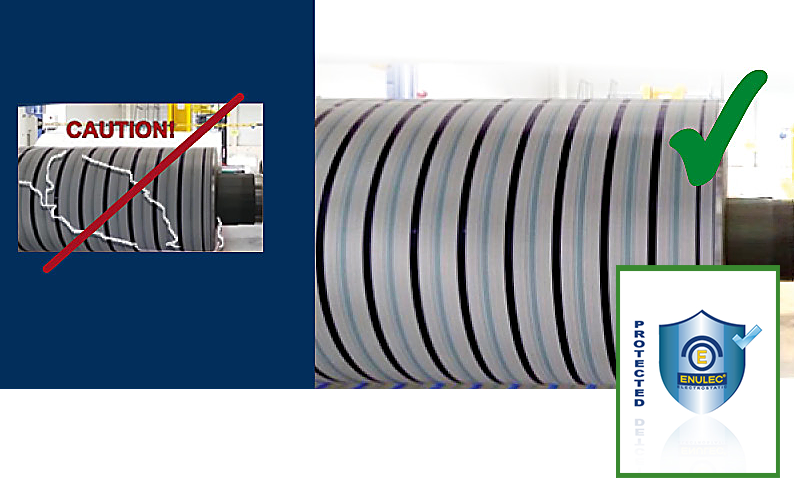

Overcharged impression rollers and operator faults are a thing of the past.

Accordingly, this new ESA system makes printing of various film substrates significantly safer by preventing high trapped charges from discharging uncontrollably. Compared to other ESA systems, this innovative solution fully neutralises the electrostatic charges on the film web and greatly reduces trapped charges ( double layer charges ) in the film substrate.

The background:

A film never forgets

The memory performance of a film is comparable to that of an elephant. It forgets nothing.

All the energy it encounters in its manufacturing and production process is stored in the layers of the substrate and affects subsequent production processes.

= The voltage can rise up to 300.000 Volt

This is the reason why the cause of static charges cannot always be located where they can ultimately be measured. The continuous changes in the molecular structure of the film can cause the sudden appearance of high electrostatic charges. In addition, electrostatic charges can “hide” themselves outwards as charge bilayers. The Enulec ESA system counteracts charge bilayers and prevents a reduction of the ESA effect, even under difficult printing conditions and with different types of film. Enulec’s capacitance-free high-voltage generation in conjunction with the impression rollers ensures optimum printing results in a gravure press and significantly reduces waste and make-ready times.

► Avoid critical static charges in film substrates

► Monitoring of the impression rollers and ESA conditions on the ESA panel.

► Safety control recorder for all ENULEC devices and roller parameters (log file).

► Elimination of any combination of double layer and conventional charges.

► Highest safety standards guaranteed!

Static charges are measured by Enulec Static Inline Control. Implemented in the Roto-Green Advanced, it offers a suitable complement for controlling static charges for printing and converting processes. This technology is used by major packaging manufacturers and leading gravure printing press manufacturers.

The system measures the static charge on the substrate and triggers an alarm when a set threshold is exceeded. The state and progression of static charges on the substrate are recorded gaplessly. Static Inline Control is ideally installed after the unwinder and before the rewinder.