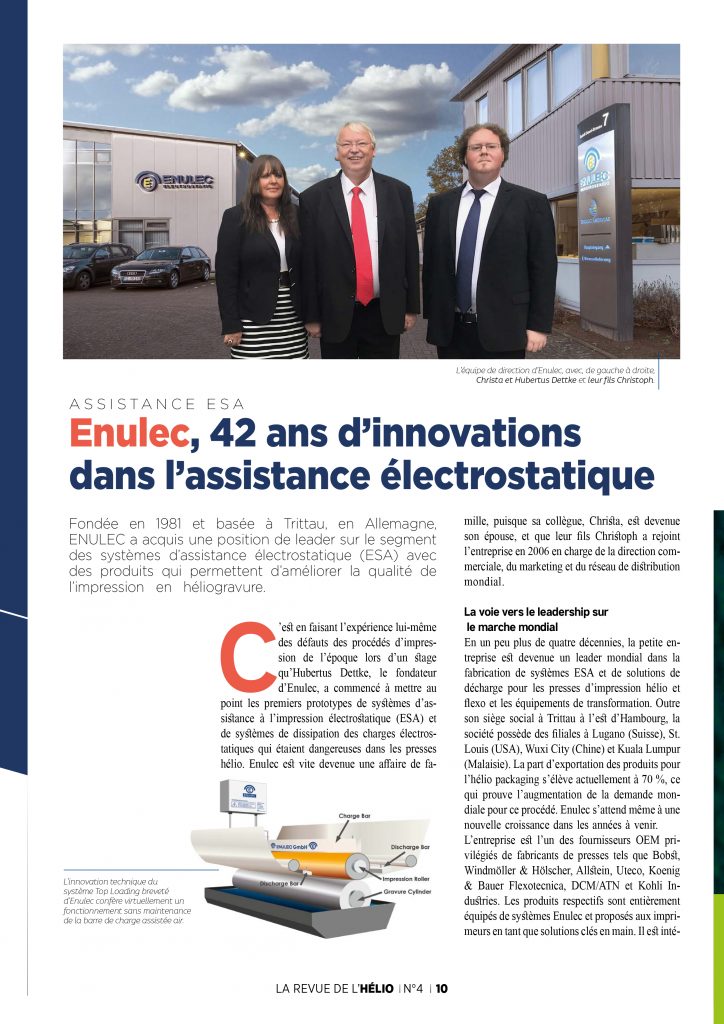

Enulec, 42 ans d’innovations dans l’assistance électrostatique

Fondée en 1981 et basée à Trittau, en Allemagne, ENULEC a acquis une position de leader sur le segment des systèmes d’assistance électrostatique (ESA) avec des produits qui permettent d’améliorer la qualité de l’impression en héliogravure.

C’est en faisant l’expérience lui-même des défauts des procédés d’impression de l’époque lors d’un stage qu’Hubertus Dettke, le fondateur d’Enulec, a commencé à mettre au point les premiers prototypes de systèmes d’assistance à l’impression électrostatique (ESA) et de systèmes de dissipation des charges électrostatiques qui étaient dangereuses dans les presses hélio. Enulec est vite devenue une affaire de famille,

puisque sa collègue, Christa, est devenue son épouse, et que leur fils Christoph a rejoint l’entreprise en 2006 en charge de la direction commerciale, du marketing et du réseau de distribution mondial. La voie vers le leadership sur le marché mondial en un peu plus de quatre décennies, la petite entreprise est devenue un leader mondial dans la fabrication de systèmes ESA et de solutions de décharge pour les presses d’impression hélio et flexo et les équipements de transformation[…]

LA REVUE DE L’HÉLIO N°4 10

Internationale Auszeichnung für Traditionsunternehmen

ENULEC mit AWARD der European Rotogravure Association ausgezeichnet

[…]ENULEC geht den Weg der Digitalisierung be-reits seit Jahren und hat seine Forschungs- und Entwicklungsarbeit sowie die Zusammenarbeit mit Hochschulen und international führenden Maschinenherstellern zur stetigen Weiterentwicklung moderner Technologien dahingehend ausgerichtet. Dieses Jahr wurde diese Arbeit gekrönt mit einem AWARD der European Rotogravure Association. In der Kategorie Neuheiten konnte die ENULEC GmbH mit ihrer innovativen ESA-Technologie, einer automatisierten Prozesskontrolle in der elektrostatischen Druckhilfe, die Jury überzeugen. Das neue Verfahren lässt Software und Hardware autonom interagieren und vereint ESA-Technologie sowie Mess- und Entladesysteme zu einem neuartigen innovativen Produkt der ENULEC Technologie.Published in MARKT / 02. Dezember 2023

Enulec – 40 years of innovations in the field of electrostatics

By Armin Karl Geiger

Founded in 1981 and headquartered in Trittau, Germany, Enulec GmbH has established a leading market position in the field of electrostatic printing assist systems (ESA) with quality-enhancing products for gravure package printing.

[…]What is the secret of a company that started out as a small family business in the 1980s and has since become a global market leader in the manufacture of ESA systems as well as discharging solutionsfor gravure and flexo printing presses and converting equipment? On the one hand, it is probably the focus on a manageable range of high-quality products that are continuously improved. On the other hand, over the years Enulec has built up a dense global sales and service network. […]Enulec is the preferred OEM supplier for renown press manufacturers such as Bobst, Windmöller & Hölscher, Allstein, Uteco, KBA Flexotecnica, DCM/ATM and Kohli Industries. The respective products are fully equipped with Enulec systems and offered to printers as turnkey solutions. This configuration offers extremely safe and highly effective ESA and discharging systems, designed for even the toughest production conditions and available for both new and existing presses. In addition, new technologies are constantly being developed in close collaboration with research institutes such as the Stuttgart Media University, Western Michigan University in the USA and the College of Engineering and Technology in Pune, India.[…]

Published in Flexo+Tief-Druck 1-2022

ESA- a reliable technology not just for gravure package printing

By Ansgar Wessendorf

For many years, Enulec of Germany has specialized in the production of electrostatic print assist systems (ESA) Jor gravure printing applications. However, package printing, with its extensive use of widely differing film substrates, is still a particular challenge for the reliable application of ESA systems.

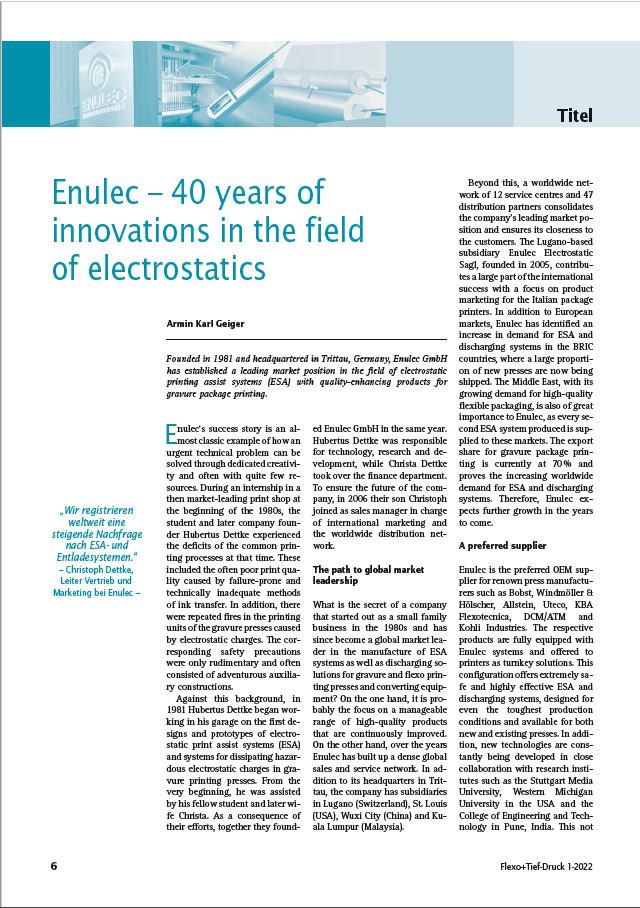

[…]The Enulec ESA RotoFilm satisfies the specific requirements of the packaging printing market. The main feature of the top-loading system is a virtually maintenancefree, air assisted charging bar. lt also offers a reduced gap between charging bar and impression roller and sufficient electrostatic assist even at low speeds.Another feature of ENULEC ESA systems is “Balances Charging”. This patent pending process balances the charges on the impression rollers in gravure presses, which in turn significantly reduces the charging of the films. However, the use of this system also increases reliability when printing paper and cardboard substrates, and several European gravure press manufacturers have confirmed its effectiveness. […]Published in Gravure Global Edition 2021

From a garage to a leading supplier of eledrostatic assist equipment

Everybody knows the success story of Microsoft, starting as a garage start up and developing into a world company, which fundamentally changed the world of communication. Not that spectacular is the story of Enulec, but the company also started in a garage and eventually became a worldwide leading supplier of electrostatic assist equipment, which improves ink transfer from the gravure cells onto the substrate, and thereby avoids missing dots. Hubertus Dettke, who studied electronic engineering and made an internship with the Swiss ESA supplier Spengler, founded Enulec (Energieübertragungselektronik – energy transfer electronics) still as a student together with his wife Christa, and they actually began with their activities in the garage of their private house.

Now, thirty-six years after its founding, Enulec’s modern premises and headquarters are located in Trittau, not far away from the north German harbour city of Hamburg. Over thirty highly qualified engineers and technicians are employed here to develop and manufacture ESA equipment for the packaging, decorative and publication printing industries. There are subsidiaries in Lugano, Switzerland and in St. Louis, USA, as weil as service centres and trade partners around the globe to support their worldwide customers. Altogether more than 7500 ESA installations from Enulec are now in operation all over the world. […]

Published in Gravure News 182/18

Gravure printing without missing dots

By Ansgar Wessendorf

Electrostatic printing assist (ESA) generally improves print quality, since it helps to eliminate missing dots. But if the press operator has selected the wrong ESA system or uses it incorrectly, it can itself cause problems with gravure printing presses.

On modern gravure printing press-es for decor and flexible packaging, ESA is standard equipment. ESA is decisive in ensuring that the ink is transferred from the cells of the gra-vure cylinder to the substrate, thus improving the quality of the print itself. However, setting and operat-ing the ESA improperly can lead to problems in the print run. Select-ing the right system and observing a few basic rules can prevent such problems arising.

Charging the impression roller with an electrostatic charge generates an electrostatic static field between the impression roller itself and the grounded gravure cylinder which exerts a force on the ink in the cylinder´s cells. This force en-sures that nearly all the ink in the cells is transferred to the substrate. In this way, ESA systems supports a proper print.

The ESA principle is based on the fact that an electrostatic charge is drawn towards an opposed charge surface until equilibrium is achieved. The ink has the same neu-tral charge as the gravure cylin-der, while the substrate is positively charged. Electrostatically charging the impression roller changes the surface tension of the ink in the cells of the gravure cylinder, the closer the ink approaches the web. The ink is pushed upwards along the walls of the cells by the electrostatic force. It is polarised in the cells and extends itself, so that the only way out is up, until it comes into contact with the substrate. […]

Published in Flexo & Gravure Global 2-2014

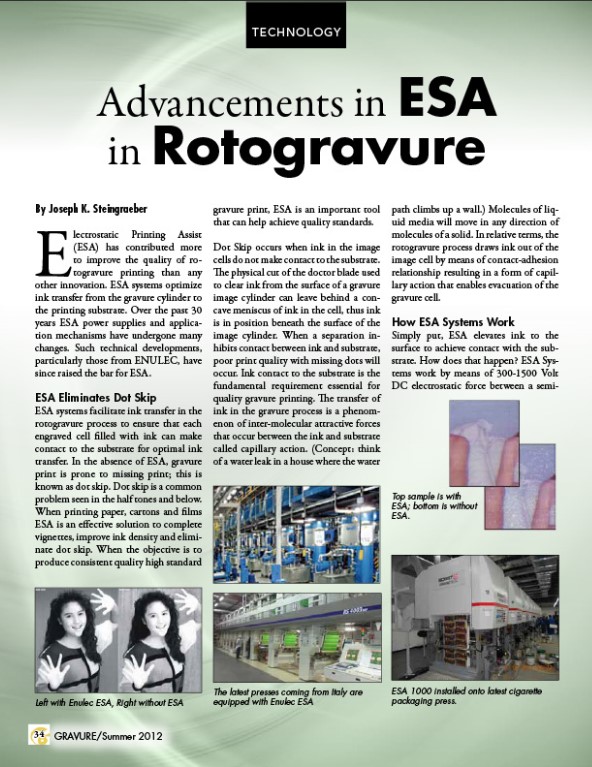

Advancements in ESA in Rotogravure

By Joseph K. Steingraeber

Electrostatic Printing Assist (ESA) has contributed more to improve the quality of rotogravure printing than any other innovation. ESA systems optimize ink transfer from the gravure cylinder to the printing substrate. Over the past 30 years ESA power supplies and application mechanisms have undergone many changes. Such technical developments, particularly those from ENULEC, have since raised the bar for ESA. […]

ENULEC designs and builds only capacitance-free high voltage generators having high internal resistance that enable optimum power transfer to the ESA impression roller and increases the performance of the ESA system considerably. With capacitance free technology, the ESA charge bars can be guaranteed safe and current-free immediately after the system is switched off as there is no residual charge in the system. Alternatively, when the ESA is switched on, high voltage is available immediately and the system can be used straight away without delay. This specially developed capacitance-free high voltage generator enables the system to be used in conjunction with ESA impression rollers having high surface resistances, including resistances outside the range normally specified. This results in a substantial increase in impression roller life related to electrical specification…

Published in GRAVURE/ Summer 2012

Slowly and steadily

This year Enulec is celebrating its 30th anniversary and is enjoying greater success than ever before

ANSGAR WESSENDORF

When a small family company like Enulec is able to perform with such great success on the world market stage for three decades, a fundamental question inevitably needs to be answered: What is the secret of this success? In Enulec’s case, there are two main factors which have contributed to their success. Firstly, it is concentration on a manageable range of high-quality products, designed to meet the needs of the market and continuously developed over the years; and, secondly, Enulec has a closely knit global network of partner companies with which close and intimate relationships have been built, often over long periods of time. These support the Trittau-based company, located close to Hamburg/D, not only in matters of service and support for their international customer base but also in the further development of their innovative products. One such product is the »air-assisted charge bar«, an Enulec innovation, protected by a registered design in Germany, which has set new standards in the gravure printing industry. And to top all of this, Enulec has recorded the highest intake of orders ever in its history during the first five months of 2011, its 30th anniversary year…

Published in FLEXO & GRAVURE ASIA 2-2011